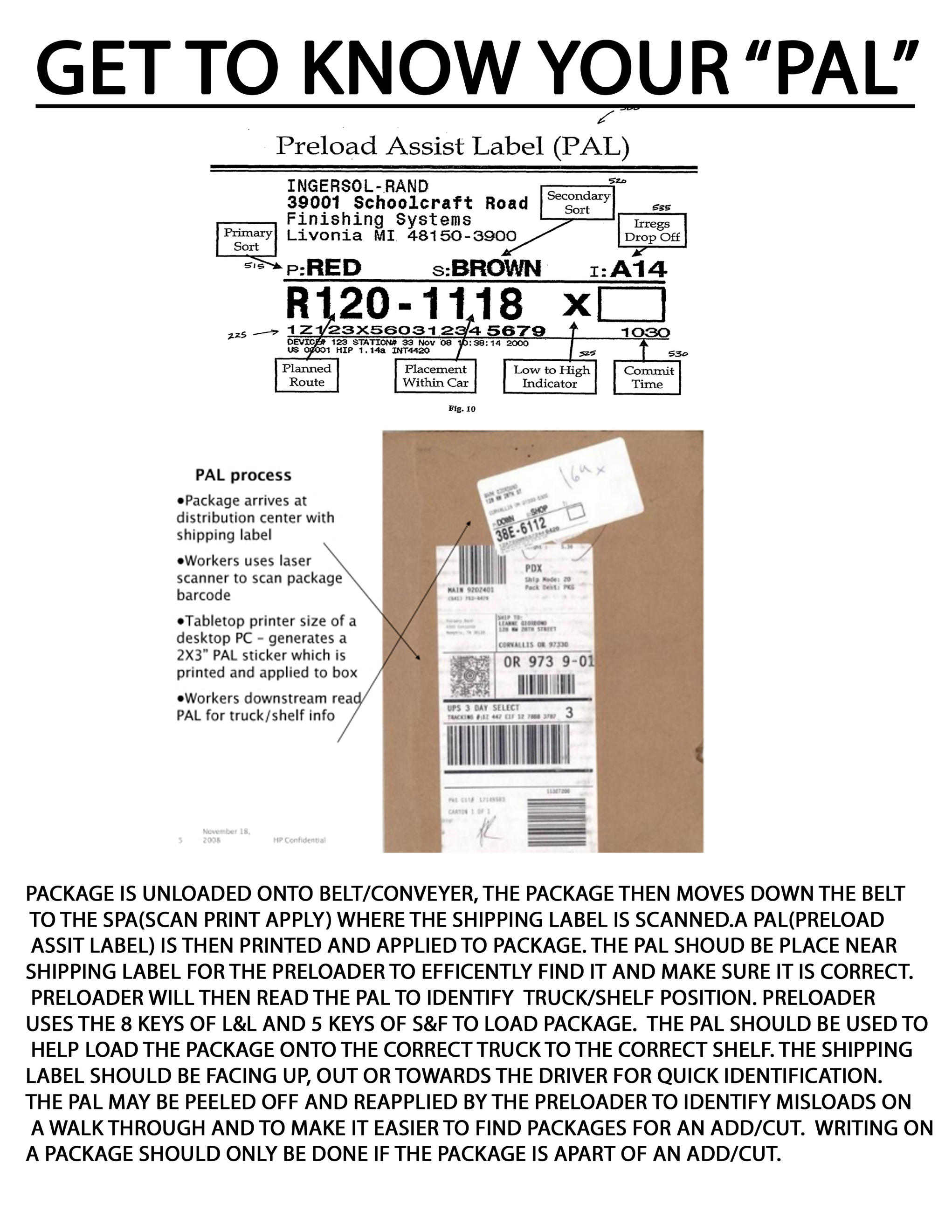

So as of Friday we have been told that our preload has to write the sequance numbers on the packages with a crayon instead of peeling and reappyling the PAL(preload assit label)also known as the SPA label (SPA is the process scan print apply). Are any other hubs with the sticker systems having to do this? As our super put it today this is coming from above his bosses bosses boss.. I find it takes me longer to write with a black crayola crayon then it does to peel and reapply the PAL, my sequencing has been way off and I get so backed up that it takes 2 ppl to help me finish at the end of the day(I load 4 trucks everyone else 3). When i peeled and reapplied the PAL I would do walkthroughs to check for misloads and my sequenceing was dead on(my drivers loved it) So after talking to a co-worker I came up with a "Get to know your "PAL"" sheet all of the preloaders agreed with it and mangament laughed at it. So I would like to know the thoughts of my fellow UPSers if you would like to print it and share it feel free to. Just don't forget to thank this lil 5'4 pissed off preloader when you agree lol... -Ryan

-Ryan

-Ryan

-Ryan

Last edited by a moderator:

that I was...... I stood there and wrote numbers from 100 - 200 on a piece of paper in front of my PT Sup and asked him to time me. Somehow....I never really had a lot of respect for our UPS IE guys.........and that feeling continues even today.

that I was...... I stood there and wrote numbers from 100 - 200 on a piece of paper in front of my PT Sup and asked him to time me. Somehow....I never really had a lot of respect for our UPS IE guys.........and that feeling continues even today.