You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The forced use of crayons for preload

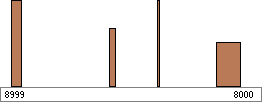

Writing HINs on packages isn't necessary. The shelves are already numbered. If you put the package in the correct spot on the shelf, you can easily find it by looking at the shelf number. Also, nothing beyond the first two digits are useful to drivers unless it's a large add cut, since gaps between used numbers are usually at least 20-40 apart. Looking at this example, you can easily see these packages are likely 89xx, 85xx, 84xx, and 81xx just by shelf position. If you're off by 100 it's not that big a deal.

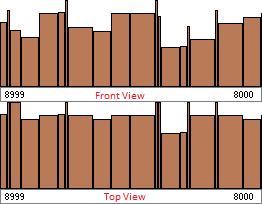

The key is to learn to load using the least width of the shelf. Packages should fit deep first, then tall. Envelopes should always fit between other packages. See example.

The key is to learn to load using the least width of the shelf. Packages should fit deep first, then tall. Envelopes should always fit between other packages. See example.

Last edited:

slaveofbigbrown

Well-Known Member

Maybe if they didn’t slam 3/4 of the days volume down the preloaders throat in the first 1 1/2 of the shift misloads wouldn’t be so bad.

MarvelousMunata

The Scapegoat With Attitude

ExactlyMaybe if they didn’t slam 3/4 of the days volume down the preloaders throat in the first 1 1/2 of the shift misloads wouldn’t be so bad.

watdaflock?

Well-Known Member

The numbers make it easier and quicker for preloaders to place the packages in order, especially later in the preload when PCs are getting stuffed.Writing HINs on packages isn't necessary. The shelves are already numbered. If you put the package in the correct spot on the shelf, you can easily find it by looking at the shelf number. Also, nothing beyond the first two digits are useful to drivers unless it's a large add cut, since gaps between used numbers are usually at least 20-40 apart. Looking at this example, you can easily see these packages are likely 89xx, 85xx, 84xx, and 81xx just by shelf position. If you're off by 100 it's not that big a deal.

View attachment 173118

The key is to learn to load using the least width of the shelf. Packages should fit deep first, then tall. Envelopes should always fit between other packages. See example.

View attachment 173126

Also - no way you ever get entire shelves loaded with packages that are all relatively the same size/height, like in your example. That's a dream world example......

Heavy Package

Well-Known Member

The shelves are already numbered.

This is what I see when I look at my preloader saying the car is all wrapped and ready to go:

Heavy Package

Well-Known Member

Here's the whole preload team posing for a pic for UPSers.com. You'll see it next week when you login to check your pay!

The numbers make it easier and quicker for preloaders to place the packages in order, especially later in the preload when PCs are getting stuffed.

Also - no way you ever get entire shelves loaded with packages that are all relatively the same size/height, like in your example. That's a dream world example......

As I stated, the shelves are already numbered. If they aren't, they should be. Yes sections get heavy and you have to shift it a bit, but you shouldn't be shifting it that much. That said, I have no issues with the numbers. I wrote them on every package that was large enough for years.

You're right, the packages aren't all similar sizes. The idea still works fine. Load the package deep first. Won't fit because too long (a rug)? Not a shelf package. Then load tall. Too tall to fit? Not a shelf package. Load those packages on the floor under the shelf. This leaves you with mostly similar size packages.

I used this method for over 8 years on multiple routes. Every single driver came in the following morning after the first time I loaded their truck and thanked me. Also, never did I work hard enough to break a sweat, nor did I have supervisors telling me to speed up. I still have them begging me to go back to preload every time I see them.

eats packages

Deranged lunatic

Have you ever wedged a rug directly above the bulkhead door.Writing HINs on packages isn't necessary. The shelves are already numbered. If you put the package in the correct spot on the shelf, you can easily find it by looking at the shelf number. Also, nothing beyond the first two digits are useful to drivers unless it's a large add cut, since gaps between used numbers are usually at least 20-40 apart. Looking at this example, you can easily see these packages are likely 89xx, 85xx, 84xx, and 81xx just by shelf position. If you're off by 100 it's not that big a deal.

View attachment 173118

The key is to learn to load using the least width of the shelf. Packages should fit deep first, then tall. Envelopes should always fit between other packages. See example.

View attachment 173126

or used a television to extend a shelf outward

DumbTruckDriver

Allergic to cardboard.

Please, please, please don't ever do that.or used a television to extend a shelf outward

eats packages

Deranged lunatic

Too late, I've already done it three times this peak season! Don't forget the soundbar you can wedge directly above!Please, please, please don't ever do that.

re: The official preload bashing thread https://www.browncafe.com/community/threads/the-official-preload-bashing-thread.375374/

Last edited:

Driver7906

Well-Known Member

I work in a hot climate and it sucks when one of those crayons melts on my shelf in the middle of July and gets all over packages and my uniform.

DumbTruckDriver

Allergic to cardboard.

And then the driver goes down a bumpy road, the tv falls off the shelf and is either damaged or crushes other packages below it.Too late, I've already done it three times this peak season! Don't forget the soundbar you can wedge directly above!

View attachment 173194

re: The official preload bashing thread https://www.browncafe.com/community/threads/the-official-preload-bashing-thread.375374/

zubenelgenubi

I'm a star

Tv's are much too light now to do either of those things.And then the driver goes down a bumpy road, the tv falls off the shelf and is either damaged or crushes other packages below it.

DumbTruckDriver

Allergic to cardboard.

True, tv's are probably too light and too well packed to be damaged, but I've had packages damaged by a tv that fell off the top shelf.Tv's are much too light now to do either of those things.

burrheadd

KING Of GIFS

I signed a big fat zero on mine and handed it to my manager and he seemed irritated. I'm still in my 30 so I feel like I should have just to stay on his good side but from what I've read that charity is a scam.

"... And we do ask that you give"

Sounds like you won’t have to worry about it in a few days

burrheadd

KING Of GIFS

So why not pay them what they are worth and give them the time to do the job correctly?

They’re disposable Why get so worked up

burrheadd

KING Of GIFS

Writing HINs on packages isn't necessary. The shelves are already numbered. If you put the package in the correct spot on the shelf, you can easily find it by looking at the shelf number. Also, nothing beyond the first two digits are useful to drivers unless it's a large add cut, since gaps between used numbers are usually at least 20-40 apart. Looking at this example, you can easily see these packages are likely 89xx, 85xx, 84xx, and 81xx just by shelf position. If you're off by 100 it's not that big a deal.

View attachment 173118

The key is to learn to load using the least width of the shelf. Packages should fit deep first, then tall. Envelopes should always fit between other packages. See example.

View attachment 173126

Have you ever seen a bricked out P-1000

PT Car Washer

Well-Known Member

Anymore all employees both Union and management are disposable labor. Like you I already have locked in my retirement but still feel an obligation to the younger generation.They’re disposable Why get so worked up

Similar threads

- Replies

- 94

- Views

- 18K

- Replies

- 34

- Views

- 7K